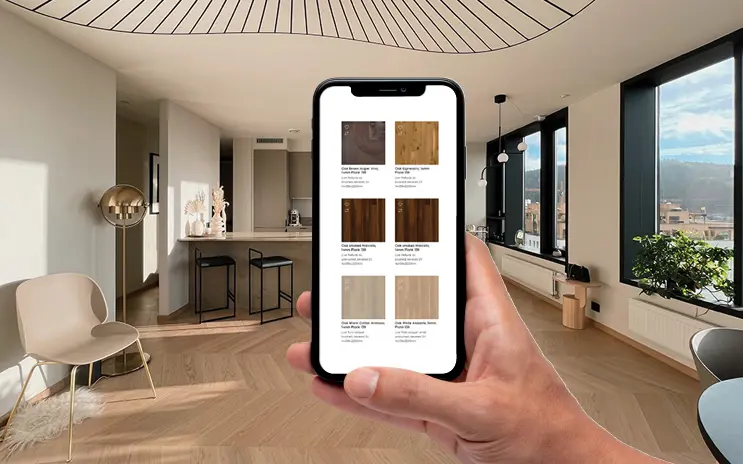

Bring your personality into the room with BOEN hardwood floors.

Nature displays the most incredible colours and materials that give us great inspiration and are becoming more and more important for us. We want to show how wood floor is so diverse and exceptional, and that there is a product for every personality and style.